DEEP TUBE WELL, DTW

installation / boring / construction / drilling

& DTW Assessment Report

আমরা Professional (B. Sc. Engr. দিয়ে কাজ করি) ও আমাদের বাস্তব অভিজ্ঞতা রয়েছে,

We involve in Installation, Testing, Commissioning and Operations & Maintenance of deep tube well

A deep tube well is a type of water well-constructed by boring along.

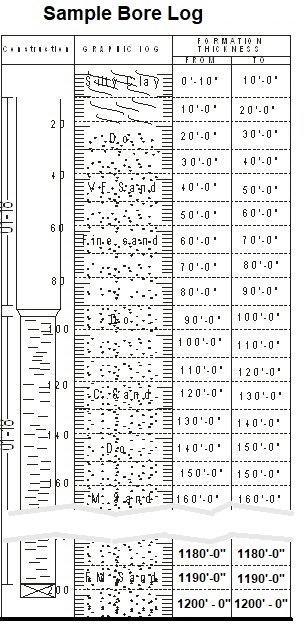

Characteristics

- Depth: The specific depth depends on the local geology and aquifer.

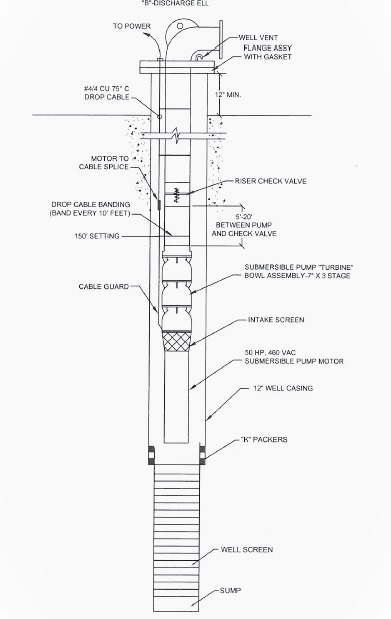

- Pumping Mechanism: Water is typically drawn to the surface using powerful submersible pumps or turbine pumps.

- Diameter: They generally have a larger diameter compared to shallow hand-operated wells.

- Water Quality and Yield: Deep tube wells often provide a more reliable and sustained water yield, especially during droughts. The water is often contaminants with higher concentrations of natural minerals like iron or calcium.

Components

The primary components of a deep tube well system include:

- Borehole: The actual hole drilled into the ground.

- Casing Pipe: A tube inserted into the borehole to prevent the well from collapsing during construction.

- Well Screen (Strainer): A slotted section that allows water to flow into the well while preventing the entry of excessive sand or silt.

- Gravel Pack: A layer of graded gravel placed in the annular space around the screen to act as an additional filter, further preventing sand entry.

- Sanitary Seal: Grouting (often with cement or bentonite) near the surface to ensure no contamination seeps down the outside of the casing.

- Pump: Mechanical equipment, usually a submersible pump, installed to lift the water to the surface.

- Platform/Well Head: A concrete base at the surface for stability and hygiene, often with a cap to protect the well opening.

- Colmn Pipe: Tube with fixing a pump-motor set up to water table and pumping water through tube.

Applications

Deep tube wells are widely used in areas where shallow groundwater is scarce, unreliable, or contaminated (e.g., by salinity or arsenic). Their primary applications include:

- Domestic Water Supply: Providing safe drinking water for communities and households.

- Agriculture: Large-scale irrigation of fields.

- Industrial Use: Supplying water for various industrial processes.

Well construction Using Methods:

- Water Jet Method,

- Reverse Circulation Method by the help of mechanical / hydraulic rotary rig,

- Inverted Method and

A borehole rig, or drilling rig, is a specialized machine designed to mechanically drill deep hole into the Earth’s surface. These rigs are used for accessing underground resources like water, oil, and natural gas, and for construction and environmental investigations.

Key Functions

The primary purpose of a borehole rig is to penetrate different layers of soil and rock to a desired depth.

- Rotational torque(spinning the drill string and bit)

- Downward pressureor weight on the drill bit removes the rock cuttings from the hole and carries them to the surface, allowing the drilling to continue deeper.

Main Components

While designs vary, most borehole rigs share core components:

- Power Unit,

- Derrick/Mast/hoisting system,

- Rotary Head/Top Drive,

- Drill String:A series of connected hollow steel pipes.

- Drill Bit,

- Circulation System:Includes mud pumps or air compressors to circulate drilling fluids or air to cool the bit and remove cuttings.

- Hoisting System:A winch and cable system used to raise and lower the drill string and casing.

Types of Borehole Rigs

Rigs come in various sizes and configurations depending on the job and terrain:

- Portable/Man-Portable Rigs:Small and lightweight, used for shallow wells or in remote.

- Truck-Mounted Rigs:Offer good mobility on roads and are commonly used for water well drilling.

- Crawler-Mounted Rigs:Mounted on tracks, providing excellent stability and mobility on rough or uneven terrain, often used in mining and foundation drilling.

- Skid-Mounted Rigs:Mounted on a steel frame.

গভীর নলকূপ ফেল করা কারণ বা ৫/৭ বৎসরে ফেল বা পানি কমে যাওয়ার কারণঃ

- (বা প্রয়োগ) না জানা,

- Gravel Packing হিসাবে গড়-মিল,

- Gravel Packing ঠিক স্থানে না দেয়া,

- Filter সঠিক পরিমান ফাঁকা না থাকা,

- Seal Coat এর ব্যবহার না বুঝা,

- Soil Collection পদ্ধতী ঠিক না থাকা,

- Ground Water Hydrology-তে ধারণা না থাকা,

- UPVC ও Carbon Steel এর ব্যবহার না জানা, ইত্যাদি, ইত্যাদি, …।

Life & Performance of Deep Tubewell improves through proper maintenance. The perforations can be cleaned by adding chemical with agitation and surging for removing the incrusting deposits.

The yield of the well may decrease due to the deposition of incrustation of fine particles of silt-clay near the screen. This can also be removed by Chemical effective treatment.

Experiance

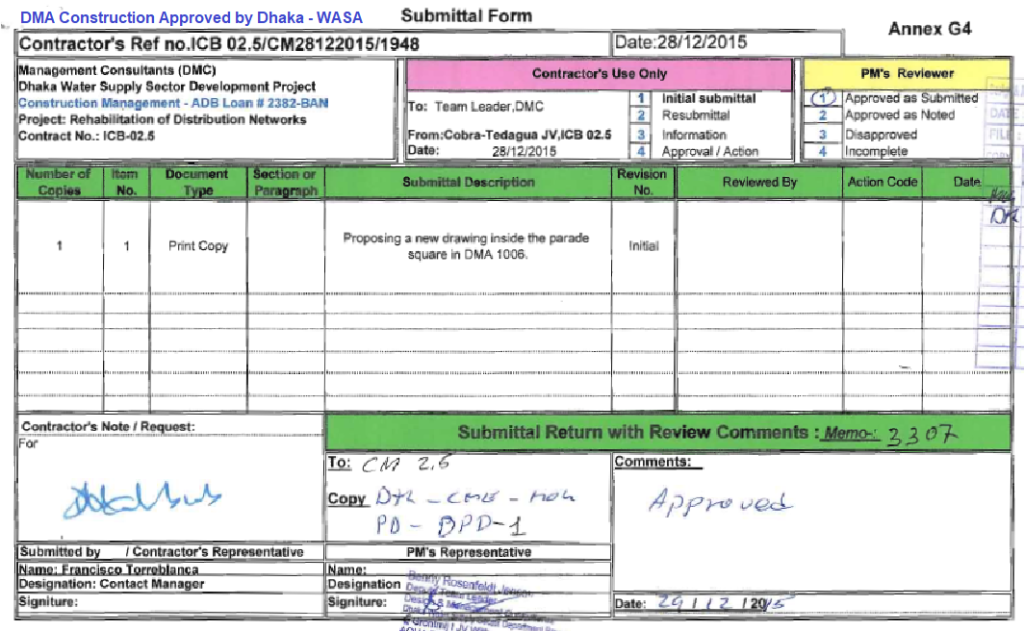

Deep Tube Well (DTW) & Water Treatment Plant (WTP), Gob & Private:

- Involved 600+ no. of DTW, GoB (D-WASA, DPHE, Cantonment etc.) & Private:

- Constructed 70m to 360m depth,

- Size: 50 – 200mm x 200 – 450mm,

- Capacity: 0.20-250m3/Hr

- Involved 50+ no. of WTP, GoB (D-WASA & DPHE) & Private:

- Constructed 0.20-200m3 and 650m3 Capacity

We involved in more than 600 hundred Deep Tube Well by the name of Alams Engineering Services or Collaboration with others company.

Name of few companies (We work all over Bangladesh):

- Dhaka WASA, (16 to 18 x 6 to 8. 800ft to 1250ft)

- Department pf Public Health Engineering, DPHE, (08 to 16 x 04 to 8, 600ft to 1000ft))

- Baraind Multipurpose Dev. Authority, BMDA: বরেন্দ্র মাল্টিপারপাস ডিভিলপমেন্ট অথরিটি (BMDA) প্রকল্পে ১২,০০০টির থেকে বেশী গভীর নলকূপ রয়েছে। আমরা তত্বাবধান করেছি ৫৮০টি গভীর নলকূপ:

- চাঁপাই নবাবগঞ্জ সদর উপজেলা : ১৫০টি গভীর নলকূপ,

- শিবপুর উপজেলা, চাঁপাই নবাবগঞ্জ : ০৫০টি গভীর নলকূপ,

- গোমস্তাপুর উপজেলা, চাঁপাই নবাবগঞ্জ : ১৪০টি গভীর নলকূপ,

- নাচোল উপজেলা, রাজশাহী : ২৪০টি গভীর নলকূপ

মোট ৫৮০টি গভীর নলকূপ

- Hamko Group, Rupgonj, Narayangonj (8”x6”, 980ftft)

- China Food Factory, Shalna, Gazipur (12”x6”, 520ft)

- Shahjalal International Airport (near 3rd terminal), Dhaka (8”x4”, 530ft)

- Bangladesh Machine Tools Factory Ltd., Gazipur, (18”x8”, 520ft)

- Madaripu Sadar Hospital, Madaripur (12×6, 850ft)

- BWDB Office Complex, Farmgate, Dhaka (10X8, 950ft)

- Moheshpur, Haluaghat, Mymensingh (6×4, 300ft),

- Madhutila, Haluaghat, Mymensingh (6×4, 300ft),

- Halughat (13 no.), Mymensingh (12×8, 300ft),

- Housing Project, Saturia, Manikgonj (6×4, 100ft)

- Housing Project, Bathuli, Dhamrai, Dhaka (6×4, 1000ft),

- Mir Aktar Industrial Area, Mirzapur, Tangail (6×4, 650ft)

- Manikgonj Passport office, Manikgonj (12×6, 650ft),

- Nayar hat, Saver, Dhaka (10×6, 1130ft)

- BWDB, Satkhira (8×6, 850ft),

- Basir Spinning Mills Ltd. (12×6, 450ft)

- Bonoful Sweets Co. Ltd. (15×6, 460ft),

- Payra Bandar See Port, Patuakhali (14×8, 1100ft)

- Ashulia Group, Narsipur, Dhamrai (8×16, 600ft)

- Essential Garments, Tongi, Gazipur (16×8, 1000ft)

- New trading Process, Tongi, Gazipur (14×8, 600ft)

- Power Plant, Borguna (6×4, 1000ft)

- Bohoria, Mirzapur, Tangail (12×8, 770ft)

- AKH Group, Bathulia, Dhamrai, Dhaka (12×8, 650ft)

- Sitakundu, Chottogram (2”x 2”, 1200ft),

- Barabkundu, Chottogram (2”x 2”, 1200ft),

- Shagorika City Area (5”x5”, 800ft)

- Pokkhali Union (8”x4”, 900ft)

- Chowfokundi, Cox’s Bazar (8”x4”, 900ft),

- Shikderpara, Cox’s Bazar (8”x4”, 900ft),

Deep Tube Well Assessment Report

A deep tube well assessment report is a comprehensive document that evaluates the performance, condition, water quality, and sustainability of a deep tube well. The report focuses on the well’s ability to provide a safe, reliable, and sufficient supply of water for its intended use, whether for drinking, domestic purposes, or irrigation.

Key subjects and components covered in the report typically include:

- Hydrogeological Information:

- Aquifer characteristics: Details about the principal and potential aquifers.

- Groundwater levels: Static and pumping water levels, and their fluctuation over time.

- Well Design and Construction Details:

- Borehole specifications: Depth and diameter of the well.

- Materials: Type and specifications of casing, screen (strainer), and shrouding materials used (e.g., PVC or GI pipes, slot sizes).

- Installation procedures: Drilling and construction methods used.

- Hydraulic Performance and Efficiency:

- Yield testing:Results from pumping tests (e.g., step-drawdown and constant discharge tests) to determine the well’s discharge rate (liters per minute).

- Drawdown analysis:Measurement of water level drawdown in response to pumping to assess well efficiency and predict future performance.

- Water Quality Assessment:

- Physical and chemical analysis: Test results for parameters such as pH, iron, manganese, chlorides, total dissolved solids (TDS), total alkalinity, and hardness.

- Contaminant testing: Analysis for specific contaminants like arsenic, lead, and microbial contamination (e.g., E. coli).

- Compliance: Comparison of water quality test results with national or World Health Organization (WHO) drinking water standards.

- Operational and Maintenance (O&M) Information:

- Pump specifications: Type and capacity of the installed pump.

- Operational status: Assessment of whether the well is functional, partially functional, or non-functional, and any needed repairs.

- Sanitary condition: Evaluation of the surrounding area, including the platform and wastewater disposal system, to prevent contamination.

- Socio-economic and Environmental Impacts (for project assessments):

- Feasibility and viability:Financial analysis using indicators like Benefit-Cost Ratio and Internal Rate of Return.

- Environmental impact: Potential negative impacts during installation, such as soil erosion or waste generation, and proposed mitigation measures.

The overall subject of a deep tube well assessment report is to ensure the well is a safe, sustainable, and effective solution for water supply needs.